The offshore series success story

The Ulstein UT704 transformed the global offshore industry, setting a new standard for anchor-handlers

In the history of shipping, there have been just a few designs that have been built in very large numbers. The Liberty tops that list with 2,710 units, followed by the T2 tanker with 533, and the Hog Islanders at 122, but they were all products of wartime needs. In peacetime, the most numerous vessels constructed have been the Liberty ship replacement design of the late 1960s. Of these, the IHI Freedom (126 built) and Austin and Pickersgill SD14 (211 built), stand out.

Another shipping sector that would produce a design built in comparable numbers was the offshore industry, whose Ulstein UT704 would eventually number 91 vessels. It would have a huge impact on the offshore industry worldwide, and set a new standard for anchor-handlers.

North Sea demands

The company behind the design, Ulstein Verft, was founded in Ulsteinvik on the west coast of Norway in 1917 as a family-owned shipbuilder and designer, primarily constructing fishing vessels.

By the late 1960s offshore oil exploration in the North Sea was well underway, and Ulstein began receiving regular enquiries for the construction of supply vessels similar to those operating in America’s Gulf of Mexico. On examining these designs, the company believed they would not be suitable for the prevailing North Sea weather conditions and accordingly began developing new types of vessels in-house.

The hulls would be broader, with a higher freeboard for safe operations in rough seas, and with much taller funnels positioned at the rear of the bridge structure to prevent any risk of allowing seawater to enter the engine room. In typical American designs the funnels were much lower and positioned further aft, outboard of the after open deck.

Offshore support vessels

As Idar Ulstein, former CEO and chair of the board explained in 2007, the growing interest in exploiting North Sea oil reserves led to a burgeoning demand for offshore vessels. With an intimate understanding of this harsh environment, and how to refine a vessel’s design to tackle it, it was clear that there was an obvious business opportunity for Idar and his team.

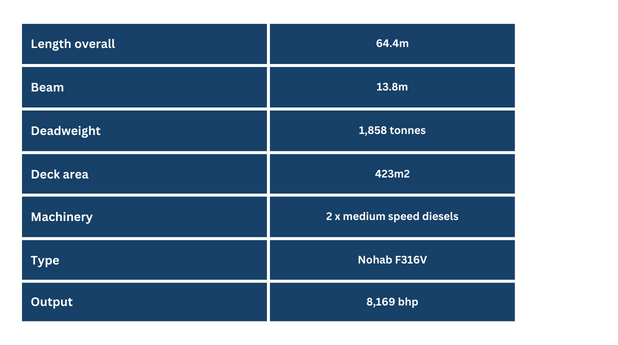

The first UT704 was powered by two Nohab main engines, producing some 7,040 bhp. It was also fitted with a 500 hp bow thruster, giving incredible manoeuvrability when compared with earlier designs. Other innovations included control of semi-enclosed hydraulic towing winch from the bridge, while visibility was also improved by giving a better view of the working deck, a factor that contributed to safety as well as to cargo and anchor-handling/towing operations.

With a bollard pull of some 80 tons and a clear after deck 37.5m long by 11m wide, built to take a cargo load of some 850 tons with a strength rating of 5 tons/m2, the design had a useful all-round capability, including anchor handling and towing for offshore rigs.

The Palau-flagged Red Bull, built in Szczecin in 1980 and now owned by Vikisa Global Ship Management of Dubai, is just one of the many UT704 vessels still in operation (Credit: Martin Lochte-Holtgreven)

UT704 production

The first UT704 to be constructed was the Alder Supplier, which was delivered by the Finnish shipyard Laivateolisuus in 1974. The first to be completed by Ulstein Verft was the Stad Sea for Stad Shipping, completed in 1975. That year 14 examples were built, and they were already seen as being ‘light years ahead of anything else available’. As such, they directly contributed to the development of virtually every subsequent anchor-handler.

Initially the UT704 appealed to Norwegian owners, but interest would eventually be worldwide. It was not only built by Ulstein, but also by other yards in Norway and in Finland, the UK, Germany, Spain, Canada, Poland, South Korea, Yugoslavia (as was), the Netherlands and Malta. Many examples remain operational today.

Over the years, the design was enhanced with higher installed power and thereby bollard pull – the Arild Viking, for example, was equipped with machinery with an output of 11,000 bhp, making her the most powerful UT704 to be built. Many would later be converted into salvage and towing vessels, and to stand-by/safety vessels.

Typical parameters