Maritime digital skills lacking but industry catching up

Insufficient knowledge of augmented, mixed and virtual reality, AI and computer modelling represent a serious skills gap according to academics, institutions and businesses.

Moving into 2025, IMarEST noted the key areas requiring focus to build a resilient and sustainable maritime future and among these were skills shortages and workforce training. As was written: “The shift towards alternative fuels, automation, and advanced digital systems has created a growing need for specialised skills in the maritime workforce.”

One such advancement is augmented technology. It has been part of the media lexicon for decades and while over ten years ago Google Glass crashed and burned, a decade on, new technologies such as generative AI and innovative thermal management techniques mean there are promising developments. Google and Samsung are betting big on Android XR, a ‘mixed reality’ operating system for headsets and smart glasses, Meta has Orion, its lightweight AR glasses, and Apple boasts a 3D camera in the form of Vision Pro.

While the consumer story has been slow – a combination of aesthetics, functionality and price points – the technology has been gaining ground in industrial applications, where it promises real wins for those working in engineering, operations and maintenance.

It is the potential for collaboration that makes the technology so valuable to industry. Later this year, for example, Dassault Systèmes will release an app called 3DLive integrated with Apple’s Vision Pro that will allow engineers and designers to collaborate on a 3D model in real time and remotely, potentially optimising design and maintenance procedures before an engineer even approaches the equipment.

Technology in the ocean

There are clear areas of opportunity in shipping, where the realities of harsh environments, stretched supply chains, a complex interplay of digital and operating systems, not to mention the financial ramifications of protracted downtime, mean anything that makes it easier and quicker to inspect, maintain and fix systems can be material, both to finances and safety.

“Connectivity and augmented reality (AR) are the key for engineers,” says Mac Macindoe, Head of Training Services at BMT, a maritime-orientated design and technical consulting firm. “They can utilise AR to support maintenance and repair whilst at sea and if the job is too difficult then the ability to connect virtually with OEMs (original equipment manufacturers) is significant.”

Maritime companies have been exploring the potential of augmented and virtual realities for some time. Florida-headquartered Crowley Maritime and ABS, a leading classification society, started exploring how to advance the use of these technologies in 2023. Indeed, Crowley now use AR goggles to provide real-time visuals of ship equipment to remote technicians. “The technology, developed by Kognitiv Spark, allows mariners and shoreside crew to more quickly complete maintenance, updates and upgrades on board with digital collaboration,” claim Crowley.

There are clear opportunities here to train seafarer engineers with real kit, to make it as effective as possible. Wärtsila has developed Wärtsilä Smart Realities, a solution that aims to provide a highly immersive training experience. Combining mathematical, physical, and environmental modelling with virtual and augmented reality, it places students on a virtual bridge or engine room to make training, be it navigation or engineering, effective in a ship environment that is increasingly complex.

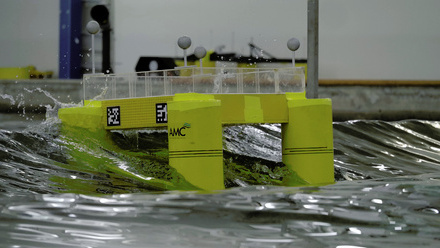

BMT themselves offer world-leading marine pilot training, maritime accident investigation and maritime simulation studies using its BMT REMBRANDT simulators with 360-degree immersive 3D visuals. The models can be tailor made to simulate specific characteristics or class of ship, from bulk carriers and container ships to tankers and tugs.

In the classroom

Universities also find this technology to be key, to help enhance learning and ensure their graduates can hit the deck ready to perform. In Aberdeen’s Robert Gordon University, students can scan a QR code and then open up an engine for dissection in a traditional classroom setting. Plymouth’s new engineering building, the £63 million Babbage Building, includes an Immersive Visualisation Suite, which comprises: “Three large high-definition display panels [which] allow for the simultaneous viewing of both 2D and 3D data, while small groups can engage with the data in a dynamic extended reality environment for an immersive, interactive experience,” according to its website.

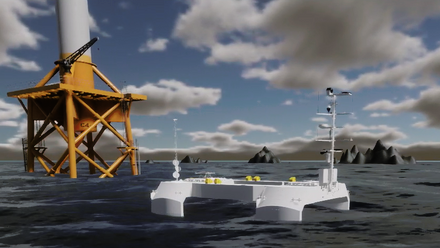

“Integrated with other campus facilities, this lab acts as a hub for real-time data exchange, facilitating collaborative research and advancing technological development across multiple sectors, including emerging fields like floating offshore wind.”

New technologies don’t just make training more accessible and collaborative. They also help those charged with designing and delivering training, particularly around the kinds of hazards and safety procedures found at sea, and ensure they are constantly evolving at speed. This matters more than ever as the industry rapidly adapts to the challenges of decarbonisation and digitalisation, whether it’s safe handling of new fuels or ensuring cybersecurity on vessels and in ports.

“High risk or high safety requirement training requires extensive training needs analysis (TNA), which is time consuming and vital to ensure training meets the requirement,” concludes Macindoe. “We are focusing on speeding up this process [by] using AI and using AI-based design tools for eLearning.”

Tell us what you think about this article by joining the discussion on IMarEST Connect.

Newsletter image: BMT REMBRANDT simulator; credit: BMT.